Tactile indicators are everywhere in the public environment: on waiting platforms, at pedestrian crossings, ramps and stairs etc. Most people understand the role tactiles play in assisting vision impaired pedestrians to navigate the urban landscape and avoid hazards. What’s less understood about tactiles is the need for precision when it comes to placement, colour, size and quality.

Vision impaired pedestrians rely on consistency for accurate interpretation of the cues provided by tactiles. Complying with Australian Standards is an essential part of the product selection and installation process. To maintain consistency, a number of factors need to be considered:

1 DIMENSIONS

Tactiles need to be manufactured to precise specifications to achieve adequate prominence without causing a tripping hazard.

2 CORRECT INSTALLATION

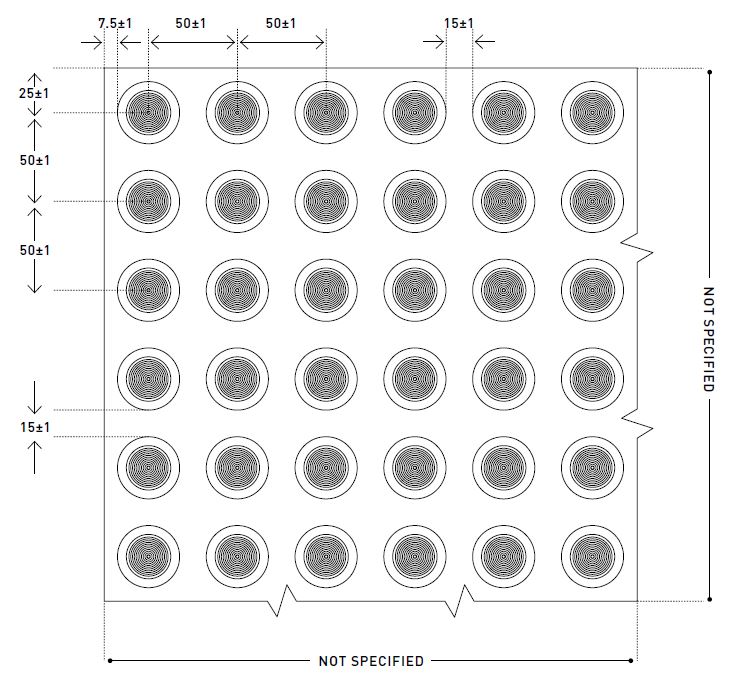

Tactiles must be installed with the correct spacing between each unit. Inconsistent spacing has the potential to cause misinterpretation which can lead to confusion, or worse – accidents. It’s important that the installer is aware of the Australian Standards to ensure that a consistent layout is achieved.

Below are some examples of incorrectly installed tactiles that do NOT meet Australian standards:

This diagram below illustrates the general TGSI pattern layout for Discrete and Integrated Warning TGSIs generally used within Australia. AS/NZS 1428.4 (2002) is widely regarded as the definitive guide in Australia for the layout, placement and positioning of TGSIs. For greater detail see AS/NZS 1428.4 (2002).

Note: there are many installation methods for attaching TGSIs to a surface/substrate. Please ensure when installing TGSIs that the installation method is applicable to your surface/substrate.

3 LUMINANCE CONTRAST

Luminance contrast contributes to the efficacy of tactile indicators for visions impaired pedestrians. The reason for this is that a large percentage of vision impaired people still retain partial vision and can detect the contrast provided by suitably coloured tactiles. When architects and specifiers select a colour, it’s important to factor in the colour of the substrate. Failure to consider the background colour could result in insufficient contrast.

In accordance with the Australian Standards, a minimum luminance contrast of 45% must be provided between the tactile indicator and surrounding substrate. DTAC® products are available in a range of colours, allowing specifiers to select according to requirements. Refer to the luminance chart for selection details. The luminance of DTAC® products conforms to AS 1428.4 2013.

4 SLIP RESISTANCE

An essential consideration when selecting tactile indicators is the level of slip resistance provided. Tactiles are often placed at hazardous locations such as bus and rail platforms, escalators, top of stairs and pedestrian crossings. It’s essential that tactiles do not increase the chance slip and fall accidents, especially in wet conditions.

DTAC® tactiles conform to slip resistance requirements.

Ratings are as follows:

STAINLESS STEEL: R11

BRASS: R11

COLOURMAX: R11

POLYRESIN / URETHANE: R12

4 QUALITY

Due to the nature of their application, tactile indicators need to withstand harsh conditions including constant foot traffic, heavy rolling loads, extreme UV levels and other natural elements such as wind and rain. Choosing hard wearing, UV Stabilised Tactiles is essential to maintain appearance and functionality. Poor quality products suffer degradation over time. Worn surfaces and faded colours eventually render tactiles non-compliant. DTAC® tactiles are extremely hard wearing and UV stabilised, meaning they have a very long service life.

DTAC® Tactiles conform to:

i) Building Code of Australia D3.8 (Read the extract)

ii) AS/NZS 1428.4.1 2009

iii) AS/NZS 4586 2013

MAKE THE QUALITY CHOICE

If you want assurance that your tactiles will comply with Australian Standards, make sure you select a quality product such as DTAC®. ABS West is the exclusive distributor for DTAC® products in Western Australia, where you can speak to industry professionals who are conversant in the relevant compliance codes. You will have peace of mind that your tactiles are installed correctly, in accordance with required standards. Likewise, if you are seeking a product with a very long service life, avoid cheap alternatives that will degrade and require early replacement.

PLEASE NOTE: ABS West no longer stocks DTAC® products. However, due to this article’s popularity, we have kept it on our website for the purpose of providing useful information. DTAC® products can still be purchased from DTAC’s head office in Melbourne.

For an overview of products stocked by ABS West, please visit the ALL PRODUCTS page.

Disclaimer: no one should act or reply upon the information contained within this document without first referring to the current AS/NZS 1428.4 and satisfying themselves that any proposed installations are in accordance with the Australian standards or with the applicable building regulations, including the Building Code of Australia (BCA), as they apply from one situation to another. Furthermore, the information provided is solely for the purposes of TGSIs and is not related to the design, configuration or formation to stairs, handrails, ramps and accessible paths depicted therein.

Interested in what ABS West is up to?

Subscribe to our Newsletter.

Submit your details and we'll add you to our mailing list:

BESPOKE SOLUTIONS

LATEST NEWS

Address: 14B Port Kembla Drive, Bibra Lake

WA, 6163

Call: +61 8 9314 4000

Email: [email protected]

Business Hours: 7am-4pm Mon-Fri

GOOGLE MAP

COLOUR DISCLAIMER: Product colours should be used as a guide only. Actual product colours can vary from the colour on your screen due to variations in monitor displays.

CONTENT DISCLAIMER: ABS West has taken all reasonable care in producing the content contained in this website. However, ABS West will not be responsible to loss or damage arising from the use of this information. The contents of this website should not be used as a substitute to detailed analysis or investigations regarding product information, or any queries the reader wishes to have answered.