BLOG

Is Sustainability an Important Guiding Principle for the Spaces you Create?

If the answer is yes, then please take a few minutes to watch & listen to our short video presentation that focuses on GECA certification.

Stainless-Steel Crash Rails at Entrance to Coles Southern River

A recent installation of Stainless-Steel Crash Rails at the entrance to Coles, Southern River Square, will help protect tiled columns against trolley impact.

We’re Fully Installed in our New Premises in Bibra Lake

We’re in our new premises at Bibra Lake and we’re fully operational. Watch our video for a quick overview of the moving-in action.

CS Pediluxe® Entrance Matting at Southern River Square

See a recent installation of CS Pediluxe® Entrance Matting at Southern River Square Shopping Centre.

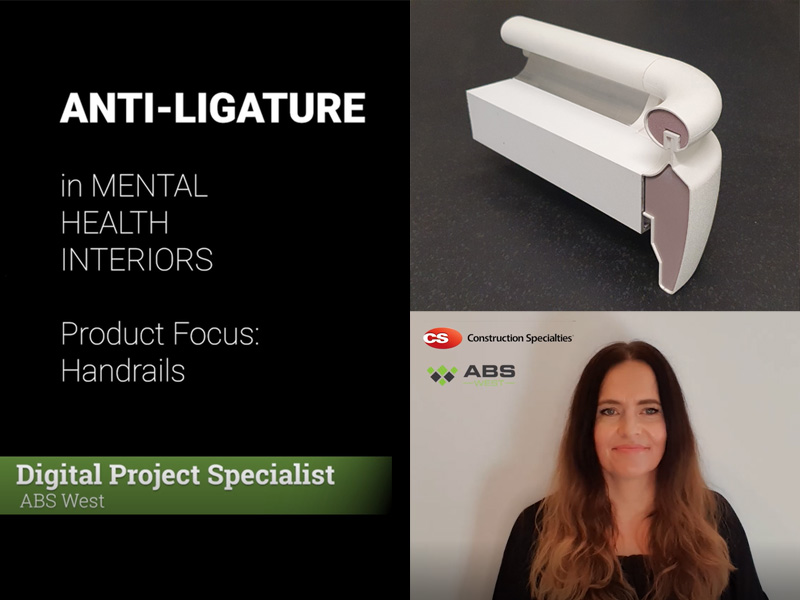

Anti-ligature Hand/Crash Rail for New Mental Health Unit

The anti-ligature Acrovyn® HRB-20AL hand/crash rail is currently being fabricated in ABS West’s workshop.

Independent Tests Prove Acrovyn’s Pathogen Resistance.

Acrovyn® is a pathogen resistant surface that’s been utilized in healthcare, aged care and other high-risk operations for decades.

Acrovyn® Features Heavily in New ICU Ward

Acrovyn® crash rails and doors for new ICU ward at major Perth hospital.

ABS West has Moved into New Premises

ABS West has moved from O’Connor to Bibra Lake. Get the details here.

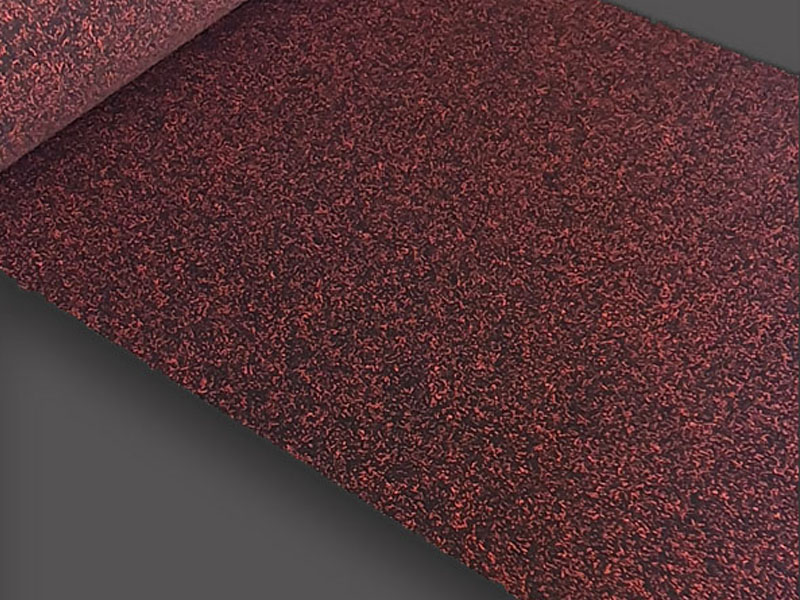

New REGUPOL everroll Colour: MARRAKESH

REGUPOL everroll Core Marrakesh contains vibrant flecks of red that add warmth and sophistication to commercial interiors or gym & fitness zones.

Coastal Colour Pallet Using REGUPOL and Acrovyn®Ranges

See our coastal colour pallet inspired by local West Australian scenery using REGUPOL and CS Acrovyn colours.

ABS West Look Book – Main Categories

View ABS West’s look-book for a quick overview of our architectural products including our main REGUPOL and CS Acrovyn product categories.

Watch this Test of REGUPOL Cargo Matting

Watch this test of REGUPOL Cargo Matting. See how far the tilt-tray tips before the cargo slides.

Acrovyn by Design® at Broome Joint Response

See Acrovyn by Design® Wall and Door Protection at Broome Joint Response. The aquatic theme of this installation adds vivid colour and a sense of light to the interior space.

New-look Acoustic Underlay Website Section

The REGUPOL Acoustic Underlay section on our website has had a fresh makeover, where you can find test reports, tech data sheets., etc

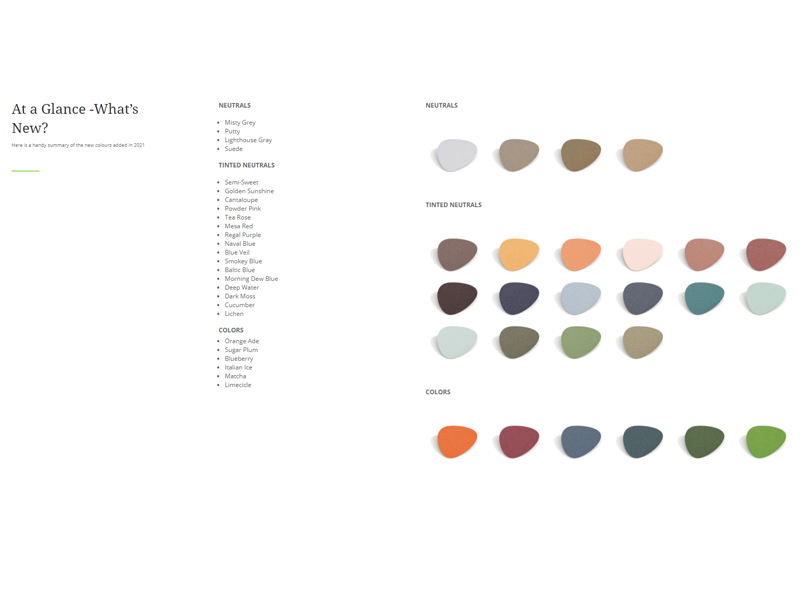

New Acrovyn® Colours – Wall & Door Protection

The stunning new Acrovyn® colours are out! Visit our colour reference page to see what’s new, what’s staying and what’s retiring.

REGUPOL everroll Flooring in Palace Cinemas Perth

Pre-sealed REGUPOL everroll flooring used at Palace Cinemas to control impact sound.

Circular Entrance Matting at 12 St Georges Tce

CS Pediluxe circular and rectangular entrance matting in Perth’s CBD.

Anti-Ligature in Mental Health Interiors

The design of mental health interiors requires special attention to ligature resistant fixtures. Watch our video…

Overview Video of Acrovyn® Hydroclad

Watch this quick overview of Acrovyn® Hydroclad, a hygienic wall covering with great impact resistance.

CS Acrovyn® Crash Rails at The Ritz Carlton

Large quantities of CS Acrovyn® Crash Rails were applied to the walls in utility areas of The Ritz Carlton Hotel.

Interested in what ABS West is up to?

Subscribe to our Newsletter.

Submit your details and we'll add you to our mailing list:

BESPOKE SOLUTIONS

LATEST NEWS

Address: 14B Port Kembla Drive, Bibra Lake

WA, 6163

Call: +61 8 9314 4000

Email: [email protected]

Business Hours: 7am-4pm Mon-Fri

GOOGLE MAP

COLOUR DISCLAIMER: Product colours should be used as a guide only. Actual product colours can vary from the colour on your screen due to variations in monitor displays.

CONTENT DISCLAIMER: ABS West has taken all reasonable care in producing the content contained in this website. However, ABS West will not be responsible to loss or damage arising from the use of this information. The contents of this website should not be used as a substitute to detailed analysis or investigations regarding product information, or any queries the reader wishes to have answered.