VIBRATION ISOLATION: manage the distribution of vibration forces

BUILDINGS | GYMS | MACHINE FOUNDATIONS | RAIL TRAFFIC SYSTEMS

In some cases, vibration forces can cause disturbance in buildings and adjacent areas. Some examples include gyms; warehouses with heavy machinery, and buildings with a close proximity to railway lines etc. REGUPOL and Regufoam® products have been developed to help mitigate vibration related issues. The physical properties of REGUPOL and Regufoam® products have been tested independently and as a result, planners can access comprehensive information to help facilitate identification of the most viable solution. Very detailed information can be found in the PDF product brochures.

VIBRATION ISOLATION: manage the distribution of vibration forces

BUILDINGS | GYMS | MACHINE FOUNDATIONS | RAIL TRAFFIC SYSTEMS

In some cases, vibration forces can cause disturbance in buildings and adjacent areas. Some examples include gyms; warehouses with heavy machinery, and buildings with a close proximity to railway lines etc. REGUPOL and Regufoam® products have been developed to help mitigate vibration related issues. The physical properties of REGUPOL and Regufoam® products have been tested independently and as a result, planners can access comprehensive information to help facilitate identification of the most viable solution. Very detailed information can be found in the PDF product brochures.

ENQUIRE ABOUT THIS PRODUCT

Vibration Isolation:

Buildings

Objectives:

Protection of Human Health & Wellbeing | Protection of Building Fabric |

Protection of Technical Equipment

REGUPOL & Regufoam

REGUPOL & Regufoam® products have been developed to isolate vibrations and perform at a constantly high level over the long term. Over 20 different materials are available and have been deployed successfully across many projects – in some cases achieving better results than the required minimum value determined in the forecast.

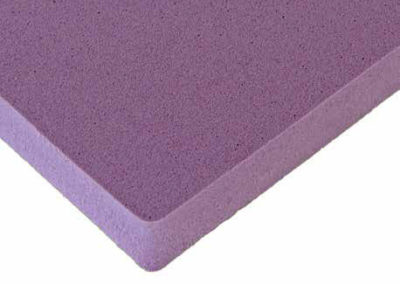

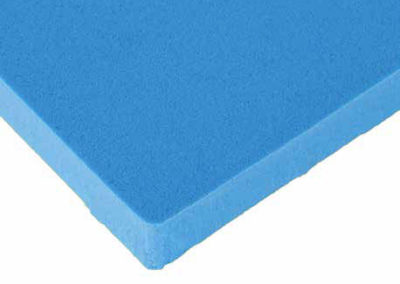

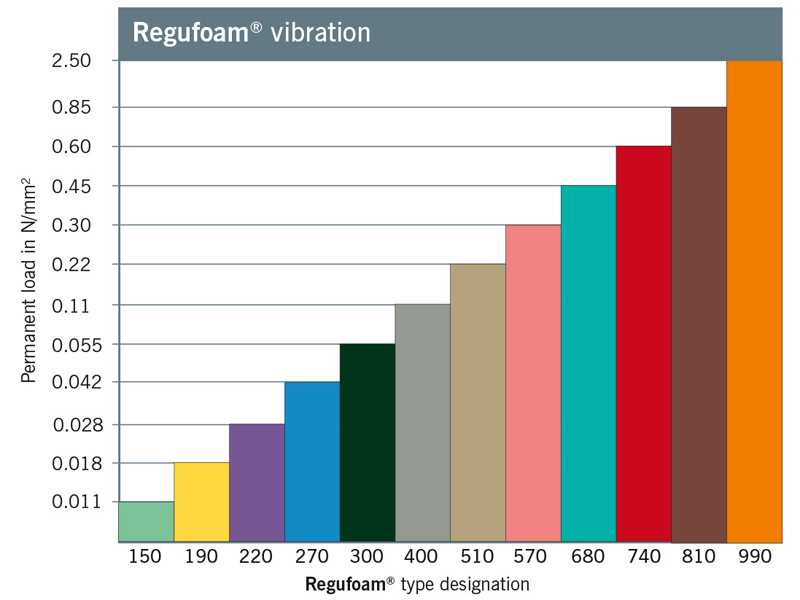

REGUFOAM® VIBRATION ISOLATION

Regufoam® is a mixed cell polyurethane foam – available in 12 different qualities.

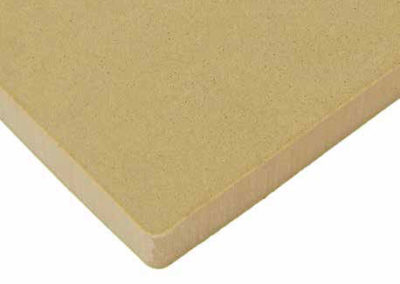

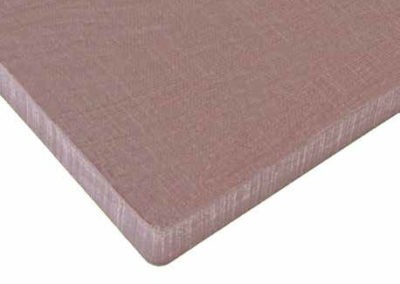

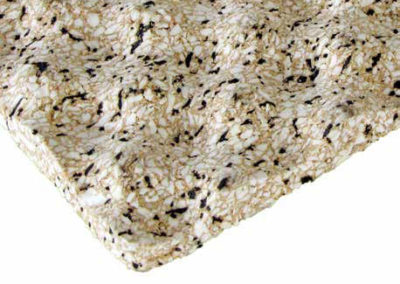

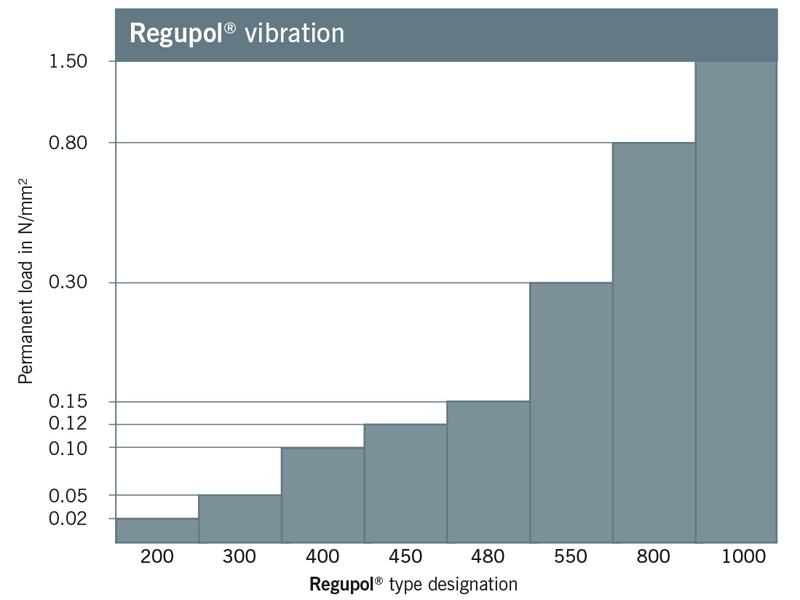

REGUPOL® VIBRATION ISOLATION

REGUPOL is a rubber-polyurethane composite for vibration isolation – available in 8 different qualities.

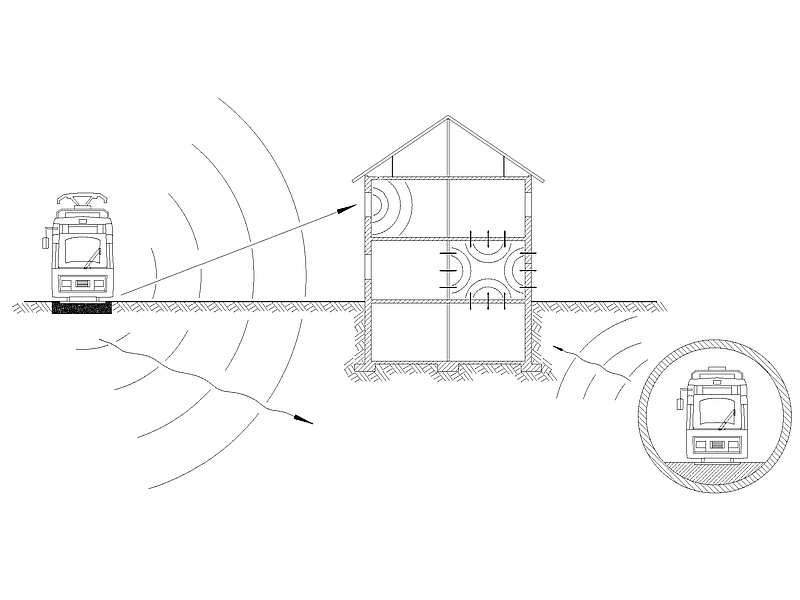

Vibration in Buildings

Common sources of vibration in buildings include adjacent railway lines, subway systems and industrial plants. The potential to encounter vibration issues increases as infrastructure density increases. Some of the detrimental effects include:

- Structural damage: When vibrations repeatedly spread through the fabric of a building, they can ultimately compromise the structural integrity of that building.

- Noise: vibrations can spread as secondary airborne sound.

- Discomfort: people living or operating in building may physically detect the vibrations or noise and suffer discomfort as a result.

- Distorted function of machinery: the functioning of machines and measuring equipment in the building may be impaired.

Applications

- Building foundations

- Railway construction

- Subways

- Facility engineering plants

- Full surface foundation bedding

- Pointed foundation bedding

- Vertical, lateral vibration isolation

- Decoupling underneath basement ceilings

- Vibration isolation of individual parts of building

- Room-in-room constructions

- Slotted walls

Benefits

- Isolation effect can be adjusted to specific requirements.

- Choice of two different product lines, giving greater scope to identify the most technically and economically viable solution.

- Precisely definable tuning frequency thanks to individual material thickness.

FAQs

- Do several layers of Regupol / Regufoam have to be adhered together? Laying several layers of REGUPOL or Regufoam® depends on the requirements for structure-borne noise insulation. If installation in several layers is specified, the insulating materials are laid loose. Several layers are not adhered or fixed to each other. To reduce the risk of leaks when laying the materials in several layers, each layer should be laid offset from the previous one so that the joints are not directly over each other (cross pattern). The joints between the single rolls are fixed with adhesive tape.

- Is it necessary to use an edge insulation strip made of REGUPOL? REGUPOL and Regufoam® is used for all perimeter areas to isolate the screed bed. This is a very important part of the installation process to avoid unwanted flanking noise through adjoining structures. The material can be cut into strips on-site or pre-cut in the factory upon request.

- How can I fasten REGUPOL & Regufoam to outside walls and rising structures? And why can’t I fasten resilient materials for decoupling structure-borne sound with commercially available insulation rawlplugs? When it comes to decoupling vibrations from the foundations of buildings or outer walls of tunnels, and when it comes to machine foundation insulation, lateral insulation is provided with REGUPOL / Regufoam® insulation panels. These are fastened preferably with polyurethane-based one-component PU adhesive Keraflex®. The surface should be capable of taking loads, clean and dry, and free of dust and grease. The adhesive is applied manually or with an air gun.Mechanical application to larger areas is carried out with REGUPOL installation aids. It is not advisable to fasten REGUPOL and Regufoam® mechanically to vertical surfaces using commercially available insulation rawlplugs because of the resulting transmission of structure-borne noise.

- What is the best way to cut REGUPOL? REGUPOL and Regufoam® can be cut on site using a snap off bladed tradesmen knife. The material can also be pre-cut in the factory upon request.

- What is the difference between structure-borne and Air-borne noise? In simple terms, the difference between structure-borne and airborne noise lies in the transmission medium. Airborne noise consists of the progressive movement of mass particles (vibrations) and is transmitted in the form of sound waves at the speed of sound (344m/s). The differing frequencies (the number of changes in pressure per second) generate characteristic tones. For example, whistling has a high frequency, compared to the low frequency generated by a growl of distant thunder. Frequencies are measured in Hertz (Hz). The audible range of a healthy young person extends from approx 20 Hz to approx. 20 kHz (20,000 Hz). Structure-borne noise is transmitted through solid structures, such as steel, wood, concrete, stone etc. This includes for example impact sound and part of the noise generated by the technical machinery installed in a building. The unit of measurement for describing sound is the decibel (“dB”).

- Why does REGUPOL and Regufoam® have to be covered with PE foil before applying to concrete? REGUPOL / Regufoam® for vibration insulation or impact sound insulation under screed is covered with commercially available PE foil (0.2 mm) to avoid any structure-borne noise bridges from forming as webs. Given REGUPOL’S open fibre structure, in-situ concrete could settle in the material and cause the resilient bedding to become stiff; in the worst case, this could lead to direct transmission of structure-borne sound. Applying the PE foil also helps to avoid webs forming between the material joints.

FOR DETAILED PRODUCT INFORMATION and TECHNICAL DATA, PLEASE DOWNLOAD THE COMPREHENSIVE BROCHURES:

Vibration Isolation:

Gyms

Gyms | Fitness Centres | Weight Rooms

The Evolving use of Gyms in Australia

Authorities receive more noise & vibration complaints than ever before, because gyms have changed in terms of where they are located and how they are used. Gyms are more readily accessible due to their centralized locations and extended operating hours, but centrally located gyms are often set within mixed occupancy buildings. The noise and vibration experienced by adjoining properties has lead to an increase in litigation and attempted evictions.

Summary of Common Issues Faced by Gym Operators

- Authorities receiving more noise & vibration complaints than ever before as many gyms now occupy mixed occupancy buildings.

- Planning authorities applying more rigorous scrutiny of development applications for gyms

- Building owners / managers seeking to evict gym tenants.

- Significant increase in litigation between authorities and gym operators.

- Increase in costs to gym operators arising from:

- extra fitout materials

- additional planning & consultancy

- restrospective acoustic mitigation

- litigation

PLEASE CONTACT ABS WEST TO RECEIVE ADIVCE AND PRODUCT INFORMATION RELATING VIBRATION ISOLATION IN GYMS.

Acoustic Disturbance

Weights being dropped onto floor surfaces and lifting platforms often cause the greatest acoustic disturbance. Similar disturbances are produced by pin and plate loaded equipment, albeit of a lesser magnitude. The noise and vibration experienced by staff and clients in adjacent shops or offices can be exceptionally disturbing.

Many factors can have an influence on acoustics so consequently, solutions need to be tailored to individual buildings, especially in light of gym development applications receiving greater scrutiny by planning authorities.

Types of Acoustic Disturbance

Acoustic disturbance falls into 3 categories:

- Vibration transmission: where vibration generated within the gym is transmitted throughout the building structure.

- Regenerated noise: where noise is produced within the adjacent area of the building resulting from the transmission of vibration throughout the building structure.

- Airborne noise transmission: where noise within the gym is transmitted through the floor/ceiling or the wall partitions into the adjacent occupancies.

Acoustic Variables - Technical Considerations

There are a number of questions to ask when determining the potential degree of acoustic disturbance, including:

- Is the gym located on a slab at ground, or on a suspended slab?

- Are the affected neighbour(s) on a slab at ground, or on a suspended slab?

- What is the type and thickness of slab upon which the building has been constructed?

- Are the affected neighbour(s) above or below the gym?

- Is the slab pre or post-tensioned concrete?

- What is the column spacing within the building?

- What is the ceiling type?

- Is there a suspended ceiling within the gym or adjacent property?

PLEASE NOTE: this is not an exhaustive list, but demonstrates the importance of assessing gyms on a case-by-case basis to devise the most appropriate solution.

Planning Parameters Affecting Individual Gyms

- State Government legislation (Acts and Regulations)

- State Government regulatory authority criteria, policies and guidelines (eg. Department of Planning, EPA, Harbour Foreshore Authority requirements including State Environmental Planning Policies etc)

- Local Council requirements (eg. LEP, DCP, Exempt & Complying DCP, Standard Conditions of Development Consent etc)

- Relevant ISO, other International and Australian Standards

- Strata By Laws and requirements

- Professional Association guidelines

- Rental lease requirements

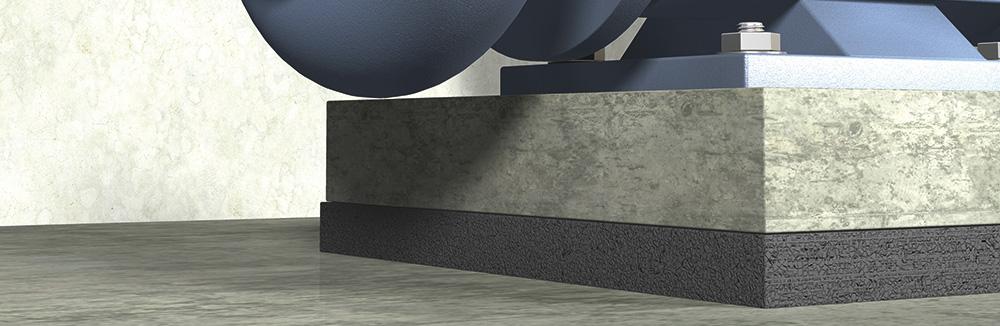

Vibration Isolation:

Machine Foundations

Objectives:

Reduce the Distribution of Vibration forces from Technical Equipment & Machinery

REGUPOL & Regufoam

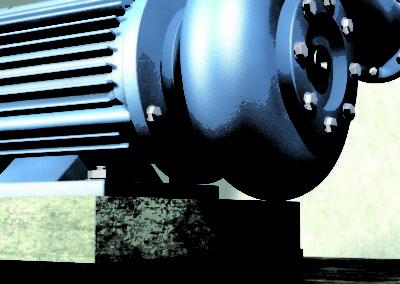

REGUPOL & Regufoam® products have been developed to isolate vibrations and perform at a constantly high level over the long term. Over 20 different materials are available and have been deployed for vibration isolation of machine foundations for over 20 years. As Regupol offer such a wide range of options, it is possible to cover a broad spectrum of vibration-technology related applications. Thanks to the rigidities of the selected material, the settlement behaviour is the same for almost all types.

REGUFOAM® VIBRATION ISOLATION

Regufoam® is a mixed cell polyurethane foam – available in 12 different qualities.

REGUPOL® VIBRATION ISOLATION

Regupol® is a rubber-polyurethane composite for vibration isolation – available in 8 different qualities.

Reducing Vibration from Machines & Technology

The most effective means of reducing the vibration impact of machinery is to use an elastic bedding such as Regupol or Regufoam to decouple the machine foundations from the building structure.

ACTIVE VIBRATION ISOLATION

- In active isolation, the spread of vibration is reduced. Generally speaking, active isolation is the preferred solution as this measure can protect larger impact areas and thus, several objects.

PASSIVE VIBRATION ISOLATION

- In passive isolation, sensitive equipment is protected against ambient variations.

Installation Guide

STEP 1: Installing the REGUPOL or Regufoam Vibration Isolation.

STEP 2: Exact cut to the dimensions of the foundations.

STEP 3: Setting up the formwork of the foundation.

STEP 4: Putting in a PE foil with a minimum thickness of 0.2mm.

STEP 5: Filling with concrete.

STEP 6: Putting in the foundation reinforcement.

STEP 7: Backfilling the remaining space with concrete and smoothing everything at the end.

STEP 8: Allow to harden then remove the formwork.

FAQs

- How do I install a floating machine foundation insulation?Basically the material and thickness of the elastomer layer depends on the acting superimposed load and on the intended degree of structure-borne noise insulation.The resilient bedding for machine foundations will only be effective on compliance with certain requirements during installation. These include, in particular, making sure that there are no direct connections (structure-borne noise bridges) between the foundations and the subsoil respectively base plate. It is also important to ensure that there is a smooth, flat surface to the base plate or foundation plate where Regufoam® or REGUPOL is going to be laid. For full-surface machine foundation isolation, Regufoam® or REGUPOL is laid across the whole surface of the foundation plate / base plate. The joints between the mats are taped down with adhesive tape which acts as a seal and prevents the mats from slipping. To reduce the risk of leaks when laying the materials in several layers, each layer should be laid offset from the previous one so that the joints are not directly over each other.The mats are cut to size at the edges of the foundation plates on site using a sharp knife. After installation, the mats are also covered with a commercially available PE foil (0.2 mm). The foil should be laid with an overlap of approx. 20 cm so that the materials are imperviously covered. At the edges, the foil should protrude by 15 – 20 cm for additional protection at the edges of the insulating materials. Regufoam® and REGUPOL are insensitive to moisture. However, Regufoam® must be protected from penetrating water and frost as the required structure-borne noise isolation properties of Regufoam® are no longer warranted in frozen state as this makes the material hard. Regufoam® must therefore be protected from penetrating moisture. During installation, the insulating materials are positioned vertically at the edges and are taped with adhesive tape. The PE foil is raised at the sides.

- What is the best way to cut REGUPOL? REGUPOL and Regufoam® can be cut on site using a snap off bladed tradesmen knife. The material can also be pre-cut in the factory upon request.

- What is the difference between structure-borne and Air-borne noise? In simple terms, the difference between structure-borne and airborne noise lies in the transmission medium. Airborne noise consists of the progressive movement of mass particles (vibrations) and is transmitted in the form of sound waves at the speed of sound (344m/s). The differing frequencies (the number of changes in pressure per second) generate characteristic tones. For example, whistling has a high frequency, compared to the low frequency generated by a growl of distant thunder. Frequencies are measured in Hertz (Hz). The audible range of a healthy young person extends from approx 20 Hz to approx. 20 kHz (20,000 Hz). Structure-borne noise is transmitted through solid structures, such as steel, wood, concrete, stone etc. This includes for example impact sound and part of the noise generated by the technical machinery installed in a building. The unit of measurement for describing sound is the decibel (“dB”).

- Why does REGUPOL and Regufoam have to be covered with PE foil before applying to concrete? REGUPOL / Regufoam® for vibration insulation or impact sound insulation under screed is covered with commercially available PE foil (0.2 mm) to avoid any structure-borne noise bridges from forming as webs. Given REGUPOL’s open fibre structure, in-situ concrete could settle in the material and cause the resilient bedding to become stiff; in the worst case, this could lead to direct transmission of structure-borne sound. Applying the PE foil also helps to avoid webs forming between the material joints.

- Do several layers of REGUPOL / Regufoam have to be adhered together? Laying several layers of REGUPOL or Regufoam® depends on the requirements for structure-borne noise insulation. If installation in several layers is specified, the insulating materials are laid loose. Several layers are not adhered or fixed to each other. To reduce the risk of leaks when laying the materials in several layers, each layer should be laid offset from the previous one so that the joints are not directly over each other (cross pattern). The joints between the single rolls are fixed with adhesive tape.

FOR DETAILED PRODUCT INFORMATION and TECHNICAL DATA, PLEASE DOWNLOAD THE COMPREHENSIVE BROCHURES:

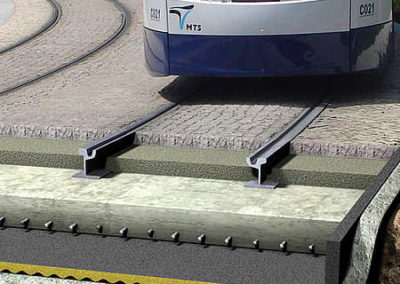

Vibration Isolation:

Rail Traffic Systems

Objectives:

Reliable Protection from Ground-Borne Vibration: light-mass-spring-systems

Reduce Vibration from Rail Traffic

Rail traffic systems produce vibrations that can be transmitted via the ground into buildings and can be experienced as shaking and secondary airborne sound. REGUPOL products have been used for over 30 years to drastically reduce the travelling of these vibrations. Even after many years of use, the vibration dampening properties of REGUPOL materials are preserved.

Product Enquiry Form

BESPOKE SOLUTIONS

LATEST NEWS

Address: 14B Port Kembla Drive, Bibra Lake

WA, 6163

Call: +61 8 9314 4000

Email: [email protected]

Business Hours: 7am-4pm Mon-Fri

GOOGLE MAP

COLOUR DISCLAIMER: Product colours should be used as a guide only. Actual product colours can vary from the colour on your screen due to variations in monitor displays.

CONTENT DISCLAIMER: ABS West has taken all reasonable care in producing the content contained in this website. However, ABS West will not be responsible to loss or damage arising from the use of this information. The contents of this website should not be used as a substitute to detailed analysis or investigations regarding product information, or any queries the reader wishes to have answered.