When constructing a new building there are certain things that simply can’t be undone at a later stage! Think of products that are used underneath the main structure of a building, no longer accessible once the structure begins to take shape. Irreversible product selections deserve the greatest prudence because poor choices can have negative impacts across the whole lifespan of a building.

To illustrate this point, let’s consider vibration isolation materials that sit between a building and its foundations. The purpose of the vibration isolation material is to mitigate vibration and noise from surrounding sources, thereby reducing negative impacts on the building and its occupants. Buildings situated in densely urbanized zones are good examples of this because they are often collocated aside busy transportation systems. Rail or subway networks interwoven into the urban landscape can transmit vibrations and secondary structure-borne noise to nearby buildings.

Integrating appropriate measures to tackle these challenges must be nailed right at the beginning of the process, because they can’t be altered retrospectively. Getting it right requires judgement of a product’s efficacy over the long-term, not just at the point of installation.

“Developers have one chance to eliminate structure-borne vibration at the outset of a project. It is quite literally the foundation of a building’s success and longevity” says Steffen Blecher, Sales Director, Acoustics Division, REGUPOL.

MAKING THE RIGHT CHOICE

So, what can developers or architects do to ensure they make the right choice when it comes to such important product selections? This issue can present a real conundrum because it’s only after vibration isolation materials are housed within finished projects that their performance becomes truly apparent.

Identify Independently Tested Products

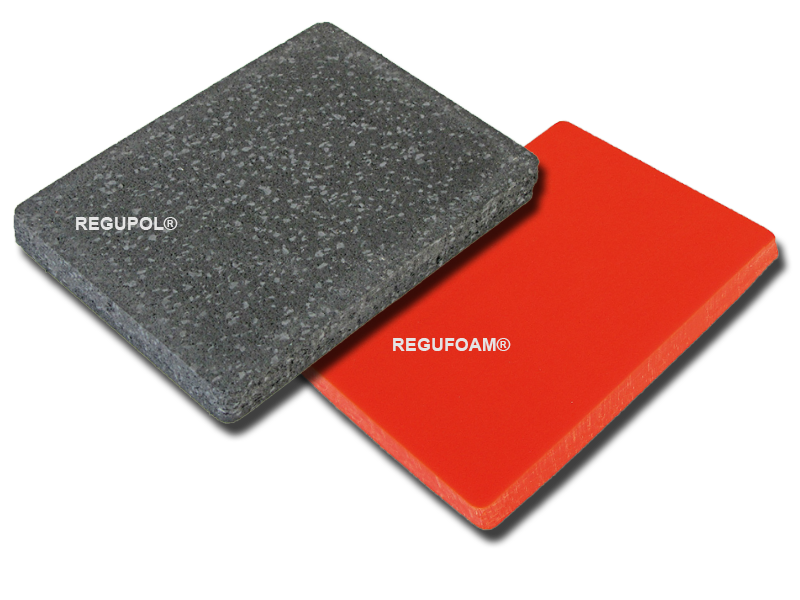

The first thing developers or architects can do is seek products that have been tested independently by trusted bodies. Examples of independently tested vibration isolation products include REGUFOAM and REGUPOL. Twelve REGUFOAM and ten REGUPOL products have undergone testing using varying load capacities, at the Karlsruher Institute of Technology in Germany.

Results from these stringent European tests demonstrate that:

1. Sound isolation levels of REGUFOAM and REGUPOL are expected to uphold the minimum requirements of most projects.

2. REGUFOAM and REGUPOL products uphold performance standards for 50 years or more because they can endure exceptionally long-term wear and tear in a variety of climate zones. To date, no other acoustic and vibration isolation products have been tested so rigorously by an institution of this calibre, so it can be said that REGUPOL is the first manufacturer globally to achieve this level of testing and resilience.

When such elite standards of testing confirm REGUPOL and REGUFOAM’s impressive performance capabilities, the bar is set high for counterpart products.

Look at Historical Evidence

Another way to assess the continuing performance of vibration isolation products is to look at historical evidence. It’s a good idea to investigate older constructions where vibration isolation products have been installed for some time. If possible, try to gain an understanding of their performance levels since the time of initial installation. Ask if vibration and acoustic readings have been taken across the years. How well did the product perform in the beginning, and can it still maintain the same performance levels years after project completion?

Let’s use a 25-year-old building to demonstrate the continuing efficacy of REGUPOL vibration 450. In 1995, this vibration isolation product was installed into a mixed-use building called Kapweg 3-8. Believe it or not, train tracks run through the basement parking area of this Berlin building. To make matters worse, groundwater and sediment have been encroaching on the site across the lifespan of this unique building. Despite these challenges, REGUPOL vibration 450 continues to maintain peak performance levels, decades after installation. We know this because readings were taken a year after installation in 1996, again in 2006 and most recently in 2018. Each reading confirms that original performance levels were maintained throughout.

WHY DO REGUFOAM AND REGUPOL VIBRATION PRODUCTS PERFORM SO WELL?

REGUFOAM and REGUPOL products work so well because they have been engineered and manufactured using the most technologically advanced material properties. They are available in a variety of thicknesses to suit individual project needs and can be layered to achieve a thickness of 50mm or more. The material acts as a separation layer between the building foundation and its substrate to offer outstanding vibration isolation, even at low disturbing frequencies. REGUFOAM is a mixed cell polyurethane foam, while REGUPOL is manufactured using high-performance elastomers consisting of rubber fibres and polyurethane. Some varieties have a dimpled underside to provide an air gap and to minimize dynamic stiffness.

WHAT IS THE SIGNIFICANCE FOR THE CONSTRUCTION INDUSTRY?

Reliable long-term vibration and acoustic isolation has the power to unlock new potential from sites that would otherwise prohibit certain building types. Mitigating the negative impacts of noise and vibration can make it a viable proposition to construct residential towers, gyms, offices and mixed-use structures in locations traditionally deemed unsuitable for these building types. With concerns in Australia surrounding urban sprawl, there is a growing movement towards urban densification to maximize the utilization of existing development zones.

“Urban planners and developers can confidently invest in real estate that was previously thought of as unfit for building when they rely on the quality of REGUPOL” concludes Steffen Blecher, Sales Director, Acoustics Division, REGUPOL.

Read more about vibration isolation on our product page:

Interested in what ABS West is up to?

Subscribe to our Newsletter.

Submit your details and we'll add you to our mailing list:

BESPOKE SOLUTIONS

LATEST NEWS

Address: 14B Port Kembla Drive, Bibra Lake

WA, 6163

Call: +61 8 9314 4000

Email: [email protected]

Business Hours: 7am-4pm Mon-Fri

GOOGLE MAP

COLOUR DISCLAIMER: Product colours should be used as a guide only. Actual product colours can vary from the colour on your screen due to variations in monitor displays.

CONTENT DISCLAIMER: ABS West has taken all reasonable care in producing the content contained in this website. However, ABS West will not be responsible to loss or damage arising from the use of this information. The contents of this website should not be used as a substitute to detailed analysis or investigations regarding product information, or any queries the reader wishes to have answered.